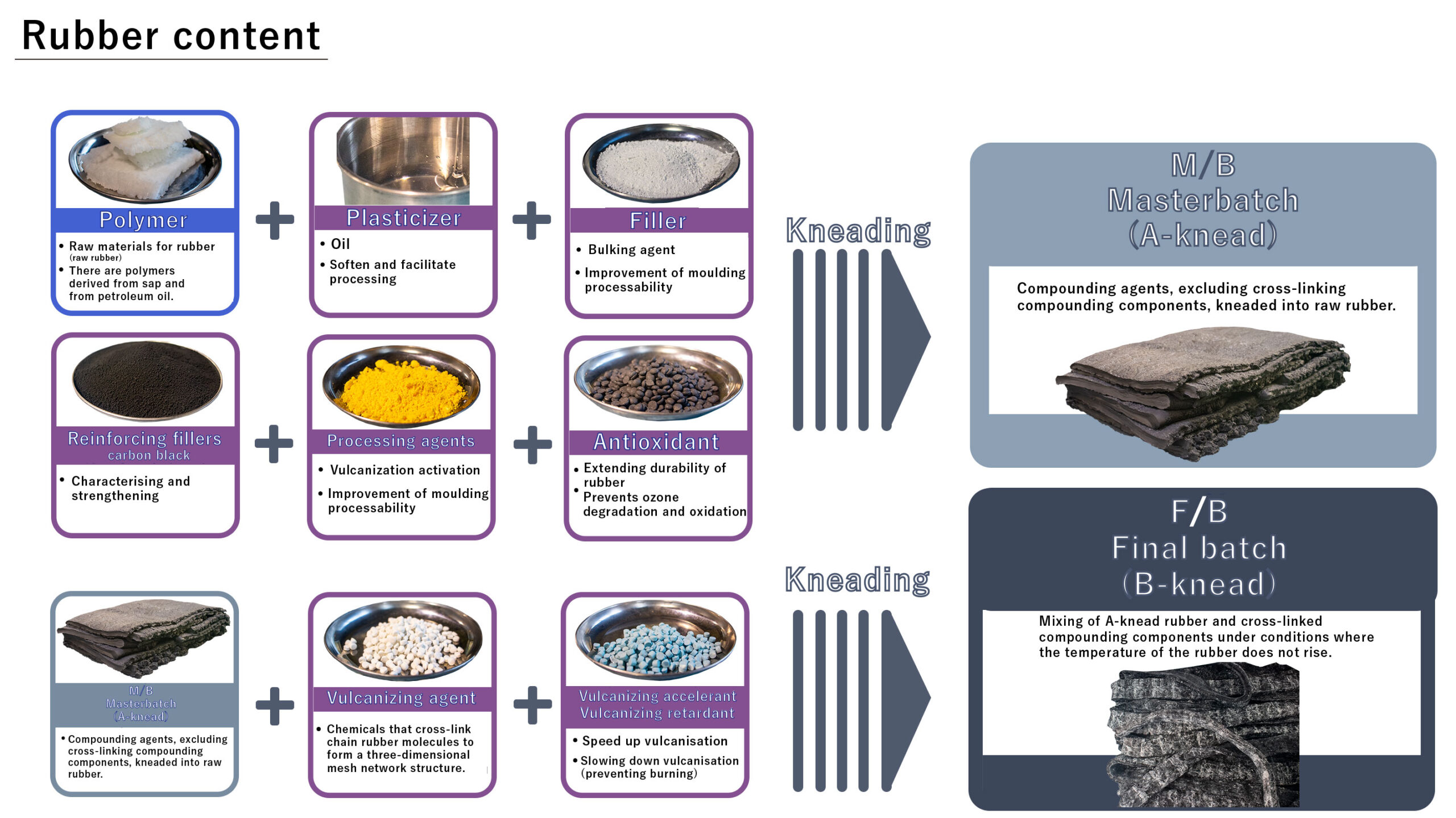

Masterbatch (A-knead)

Masterbatches (A-knead) consist of compounding agents, excluding cross-linking compounding components, kneaded into the raw rubber.

It does not contain cross-linked compounding ingredients allowing for long-term storage.

It is also possible to produce multiple types of final batches from the same master batch, such as solid or sponge, by changing the type and quantity of chemicals added in later kneading.

This is a polymer made from rubber and contains plasticisers, fillers, reinforcing fillers, processing aids and anti-ageing agents.

Final batch (B-knead)

The final batch (B-knead) mixes the masterbatch (A-knead) with the cross-linked compounding ingredients under conditions where the temperature of the rubber does not rise.

The reason for mixing and kneading under conditions where the temperature of the rubber does not rise is to avoid cross-linking.